Stacked Fin Manufacturing Process

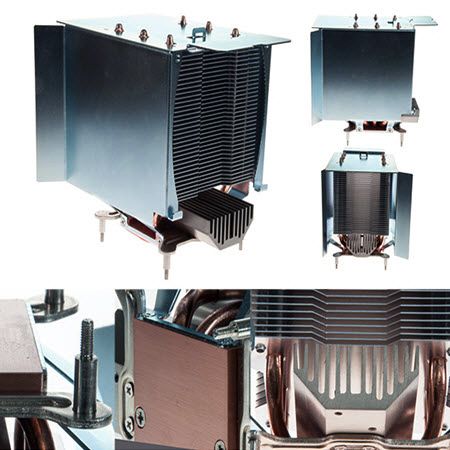

Evercool combines the efficient thermal structure of copper and aluminum to create a lightweight, high-power heat dissipation module.

What is the stacked fin manufacturing process?

Stacked Fin Assembly is a highly efficient heat dissipation structure that combines the advantages of copper heat pipes and aluminum fins. This technology uses copper as a thermal core to quickly conduct heat away from the heat source. The heat is then removed through the stacked aluminum fin structure to reduce the heat source temperature.

This manufacturing process can generally be categorized into two main structures:

1. Mechanical Press-Fit Type: Grooves are designed into the baseplate during molding, allowing the copper block or heat pipe to be pressed into place within the aluminum alloy. This tightly bonds the aluminum fins to the heat pipe, effectively improving heat transfer efficiency and contact stability.

2. Welded or Bonded Type: The aluminum fins, copper base, and heat pipe are bonded together using reflow oven welding or high-thermal conductivity adhesives, enhancing overall structural integrity and long-term thermal conductivity.

This technique significantly improves heat dissipation efficiency, making it particularly important for electronic devices requiring efficient heat dissipation.

In heat dissipation design, achieving both high thermal conductivity and low weight within high heat density and confined spaces is a major challenge.

Evercool utilizes Stacked Fin Assembly technology to cleverly combine the properties of copper and aluminum: copper's excellent thermal conductivity and aluminum's excellent heat dissipation and lightweight advantages. This integration of the two materials creates a high-performance and cost-effective heat dissipation module, ideally suited for IGBT, power module, and industrial electronics applications.

Core Advantages

- Diverse Material Combination: High Thermal Conductivity + Lightweight: Combining the rapid thermal conductivity of copper with the excellent heat dissipation performance of aluminum, this design achieves a balanced balance between heat dissipation efficiency and product weight reduction.

- Improved Thermal Conductivity: The stacked structure allows for rapid heat dissipation, significantly reducing overall thermal resistance.

- Environmentally Friendly Adhesive-Free Process: Press-fit stacking eliminates the need for adhesives, offering environmental and recyclable advantages.

- Controllable Heat Direction: The heat pipe design allows heat to be directed to specific areas, allowing for flexible configuration of heat dissipation paths.

Evercool stacked fin module integration advantages

Customizable Structural Design: Copper base thickness, aluminum fin density, and heat pipe quantity can be flexibly configured based on heat load, assembly space, and airflow direction.

DC Fan Compatibility: Integrates with Evercool's high-efficiency DC fans to create an active cooling system, enhancing convection efficiency and overall heat dissipation.

High-Reliability Verification Process: Each module undergoes thermal resistance measurement and structural strength verification to ensure long-term stability under high loads.

Flexible Application Integration: Compatible with CNC machined structures, water cooling plates, IGBT modules, or server system designs to create a complete thermal management platform.

Typical application scenarios

- Industrial IGBT or MOSFET power module cooling

- Server CPU/GPU cooling modules

- Renewable energy inverters and UPS systems

- Laser and optoelectronic application cooling platforms

- Automation equipment and thermoelectric module (TEC) cooling systems

- Gallery

- Related Products

-

DC Fan

DC fans are manufactured by EVERCOOL and are of high quality, including silent fans. They are used in various industries, including computer peripheral cooling, lithium battery charger cooling, inverter cooling, automotive electronic cooling, LED cooling, among others. EVERCOOL also offers standard DC fan products for retail sale, giving consumers the option to select and use them as required.

DC PWM Fan

EVERCOOL launched the DC PWM FAN series, the fan size ranges from 4mm to 140mm, and the thickness ranges from 10mm to 38mm. Various sizes and specifications are available for you to choose from.

CPU Cooler

EVERCOOL CPU coolers are designed for Sockets of different generations of INTEL and AMD, and according to the cooling wattage required by different CPUs, different CPU coolers are designed.