Extruded Heat Sink Manufacturing Process

Customized aluminum extruded heat sink solutions|Evercool

What is the Extruded Heatsink Process?

The Extruded Heatsink Process utilizes Aluminum Extrusion Technology to produce heatsinks with integrated fin structures.

In this method, heated aluminum alloy is forcibly extruded through a specially designed mold, forming long profiles with specific shapes — such as multiple fins.

These extruded profiles are then cut to length, CNC machined, and anodized according to design requirements to create the final heatsink product.

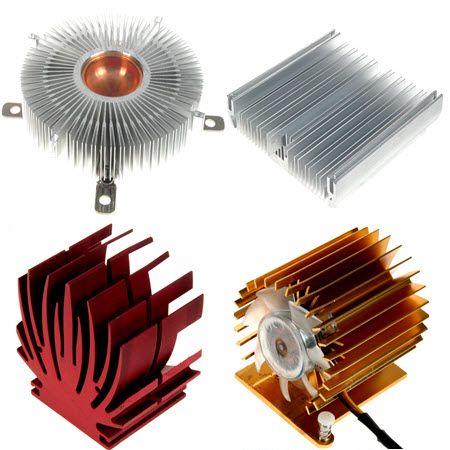

Evercool aluminum extruded heat sink modules, paired with high-efficiency DC fans, deliver efficient heat dissipation, enabling design flexibility and cost competitiveness.

From single heat sinks to large cooling systems, we can create the optimal solution tailored to your needs.

Why choose aluminum extruded heat sink?

- Cost-effectiveness: Low mold costs make it suitable for mass production.

- Material advantages: Aluminum alloy offers acid and alkali resistance, corrosion resistance, and lightweight properties.

- Design flexibility: Complex structures (such as sunflower teeth) can be created, increasing heat dissipation and convection efficiency.

- Aesthetic and diverse surface treatments: Anodizing, sandblasting, and brushing can create a variety of color finishes, suitable for applications such as industrial computer casings.

Features of Evercool Aluminum Extruded Heatsink Module

Rapid Customization: Design drawings can be directly compared to existing aluminum extrusions, shortening development time. If a similar aluminum extrusion is unavailable, the engineering team can quickly assess mold feasibility and provide design adjustments.

Precision Post-Processing: Supports multiple processes, including CNC machining, cutting, grooving, polishing, drilling, and riveting, ensuring dimensional accuracy and excellent thermal performance.

Diverse Surface Finishes: Anodizing, sandblasting, and brushing offer optimal heat dissipation and aesthetics.

DC Fan Integration: Aluminum extruded heat sinks can be directly paired with Evercool high-efficiency DC fans, increasing convection efficiency and improving heat dissipation. A variety of DC fans are available to meet diverse application requirements, including quiet operation, long life, and high air pressure.

Strict Quality Control: Each heat sink undergoes testing and assembly verification to ensure consistent quality.

Typical application scenarios

- Industrial power modules (IGBT/MOSFET)

- AI/server CPU & GPU systems

- Renewable energy inverters and UPS power systems

- Laser equipment and high-power semiconductors

- Industrial automation and welding equipment

- High-power LEDs and chassis

- Gallery

- Related Products

-

DC Fan

DC fans are manufactured by EVERCOOL and are of high quality, including silent fans. They are used in various industries, including computer peripheral cooling, lithium battery charger cooling, inverter cooling, automotive electronic cooling, LED cooling, among others. EVERCOOL also offers standard DC fan products for retail sale, giving consumers the option to select and use them as required.

DC PWM Fan

EVERCOOL launched the DC PWM FAN series, the fan size ranges from 4mm to 140mm, and the thickness ranges from 10mm to 38mm. Various sizes and specifications are available for you to choose from.

CPU Cooler

EVERCOOL CPU coolers are designed for Sockets of different generations of INTEL and AMD, and according to the cooling wattage required by different CPUs, different CPU coolers are designed.