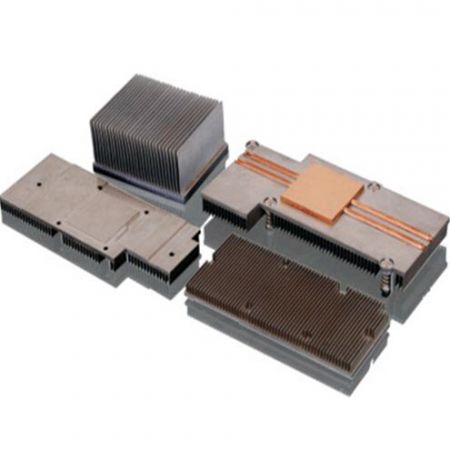

Skived Fin Heat Sink Manufacturing Process

Evercool creates an all-in-one cooling solution with ultimate thermal conductivity

What is the skived fin heat sink manufacturing process?

High-precision metal cutting technology creates a one-piece thermally conductive structure.

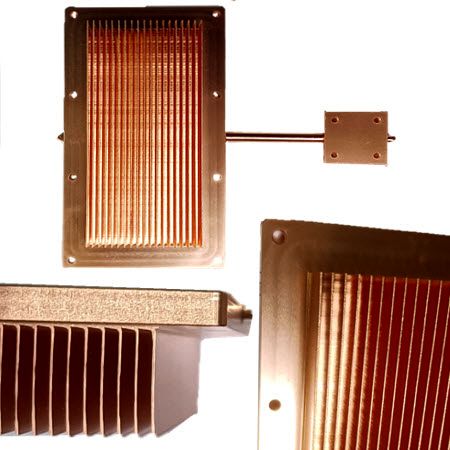

The skived fin heat sink utilizes a dedicated skiving machine to skive a continuous fin structure directly from a single block of metal (copper or aluminum).

The fins and base are made of the same material, eliminating the need for welds or adhesives, minimizing the heat conduction path and the lowest thermal resistance.

Compared to traditional aluminum extrusion processes, skived fin technology enables the production of higher fin density, thinner fins, and longer heat sinks, balancing heat dissipation efficiency with processing flexibility.

In high-efficiency servers, AI computing platforms, and industrial-grade power modules, heat dissipation efficiency is critical to maintaining system stability and extending lifespan.

Evercool utilizes precision skiving technology to manufacture heat sinks, directly skiving pure copper or aluminum into a high-density fin structure. This seamless, one-piece molding creates a heat dissipation module with excellent thermal conductivity.

This technology transcends the limitations of traditional extrusion, providing a larger heat dissipation area and higher airflow efficiency within limited space, making it the optimal solution for tackling high heat source densities.

Core Advantages

- One-piece molding, no interfacial thermal resistance: The fins and base are made of the same metal, resulting in superior thermal conductivity compared to welded or press-fit designs.

- High-density fin structure: This overcomes the fin spacing and length limitations of extruded heat sinks, increasing the heat dissipation area.

- High material flexibility: Choose from high-conductivity copper or lightweight aluminum to balance thermal performance and weight.

- No mold required: This reduces initial mold development costs and allows for rapid implementation of small-volume or custom projects.

- High-precision process control: Fin thickness and spacing can be precisely adjusted to ensure smooth airflow and stable heat dissipation.

The integrated advantages of Evercool skived fin heatsink modules

Customized thermal structure design: Fin density and airflow direction are precisely configured based on heat load and installation space.

DC cooling fan compatibility: Based on system heat density and air duct design, this module combines Evercool's high-efficiency DC fans to form an active cooling module, effectively increasing air circulation and rapidly removing heat.

Liquid cold plate compatibility: High-efficiency liquid cold plates can be manufactured using FSW (friction stir welding) technology, integrated with a skived fin structure to create an integrated cooling system, combining the advantages of air and liquid cooling to meet the extreme cooling requirements of high-power devices.

High reliability testing and verification: Each product is tested for surface flatness, thermal resistance, and structural strength to ensure long-term stable performance.

High application compatibility: Compatible with various platforms, including CNC machining modules, water cooling plates, IGBT power modules, and server thermal modules.

Typical application scenarios

- Servers and high-performance computing platforms (CPU/GPU modules)

- Cooling of power semiconductors such as IGBTs and MOSFETs

- Renewable energy inverters and UPS systems

- Lasers and medical optoelectronic equipment

- Industrial automation and thermoelectric module (TEC) cooling systems

- Gallery

- Video

- Related Products

-

DC Fan

DC fans are manufactured by EVERCOOL and are of high quality, including silent fans. They are used in various industries, including computer peripheral cooling, lithium battery charger cooling, inverter cooling, automotive electronic cooling, LED cooling, among others. EVERCOOL also offers standard DC fan products for retail sale, giving consumers the option to select and use them as required.

DC PWM Fan

EVERCOOL launched the DC PWM FAN series, the fan size ranges from 4mm to 140mm, and the thickness ranges from 10mm to 38mm. Various sizes and specifications are available for you to choose from.

CPU Cooler

EVERCOOL CPU coolers are designed for Sockets of different generations of INTEL and AMD, and according to the cooling wattage required by different CPUs, different CPU coolers are designed.