Friction Stir Welding Manufacturing Process

Customized Cooling Module with FSW Technology | Evercool

What is Friction Stir Welding (FSW)?

Friction Stir Welding (FSW) is a solid-state joining technique that produces high-strength, seamless joints without melting the materials. By generating frictional heat through a rotating tool, the material softens and plastically flows under pressure, resulting in a dense, leak-proof, and robust thermal connection.

Unlock High-Efficiency Cooling for Power-Dense Applications

High-performance servers, AI computing platforms, and industrial-grade power modules all face the challenge of high heat density and large thermal loads. Evercool leverages Friction Stir Welding (FSW) technology to integrate customized liquid cold plates with aluminum heat sinks, forming a unified fan/liquid hybrid cooling system that effectively resolves thermal bottlenecks.

This advanced thermal module solution is ideal for high-power electronics, server CPUs/GPUs, water-cooled inverters, IGBT power modules, laser systems, and more.

Key Benefits:

- No soldering materials required, eliminating leak and void risks

- Strong metallurgical bond with low thermal resistance

- Ideal for aluminum-based heat spreaders and cold plates

- Reduces tooling and production cost for large thermal modules

Evercool's Integrated Cooling Module Advantages

Custom Cold Plate Engineering:Designed based on power load, flow rate, and space constraints. Available in dual-channel, spiral, or parallel configurations with CNC-machined or extruded aluminum bases.

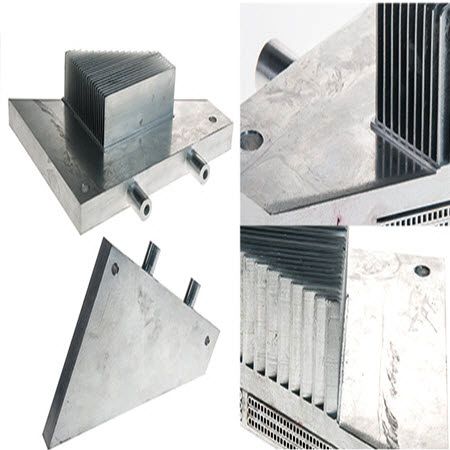

FSW Heat Sink Bonding:Aluminum fins are friction stir welded to the cold plate surface, increasing heat dissipation area. Optimized for forced-air or passive convection designs.

Fan + Liquid Cooling Integration:Combine Evercool's high-efficiency DC/AC fans with your custom water cooling system for a total cooling solution that meets performance and space demands.

Quality & Performance Testing:Each module is pressure-tested, leak-tested, and validated for thermal resistance and structural integrity to ensure long-term reliability.

Application Fields

- Server CPU/GPU hybrid liquid cooling modules

- Industrial IGBT or MOSFET power module cooling

- AI training system heat management

- Renewable energy inverters and power supplies

- High-power LED or laser cooling platforms

- Automation control boards and thermoelectric assemblies

- Gallery

- Video

Discover how Evercool applies Friction Stir Welding (FSW) technology to create high-efficiency thermal modules for demanding electronic applications. This video demonstrates how we integrate custom liquid cold plates and aluminum heat sinks using FSW, ensuring seamless, leak-proof, and low-resistance bonding. The result? A fully integrated fan and liquid cooling hybrid solution that meets the thermal challenges of modern server CPUs, IGBT power modules, and AI computing systems.

- Related Products

-

DC Fan

DC fans are manufactured by EVERCOOL and are of high quality, including silent fans. They are used in various industries, including computer peripheral cooling, lithium battery charger cooling, inverter cooling, automotive electronic cooling, LED cooling, among others. EVERCOOL also offers standard DC fan products for retail sale, giving consumers the option to select and use them as required.

Liquid CPU Cooler

EVERCOOL liquid cooler uses a pure copper base to quickly absorb the heat of the processor and effectively conduct the heat to high-density micro-fluidic channels. Through a new generation of pump drive, the coolant flows quickly through the flow channel and effectively takes away the heat. Paired with high-performance DC fans and the high-density liquid cooling radiator, it can quickly decrease the temperature of the liquid and ensure stable operation of the processor. This process ensures efficient cooling of the system, making this product ideal for your cooling solution.

CPU Cooler

EVERCOOL CPU coolers are designed for Sockets of different generations of INTEL and AMD, and according to the cooling wattage required by different CPUs, different CPU coolers are designed.