Customized Solution

Customized Thermal and Cooling Solutions

EVERCOOL has a professional team with more than 30 years of experience in cooling solutions.

With the tenet of "customer first, quality first", we provide exclusive solutions for customers' heat dissipation problems on high-temperature devices. The process is as follows:

1. Requirement Confirmation: According to customer needs, conduct discussion and analysis, applicable environment and equipment, such as wattage, heating area, ambient temperature, etc.; select materials and parts, and fully understand customer needs.

2. Discuss the Design: If the customer provides relevant drawings, etc., the design of the product that meets the customer's needs can be made according to the customer's drawing;

The tools required for design will use some design software, such as CAD, 3D modeling, etc. The design plan will be confirmed and modified by the customer to ensure that the customer is satisfied with its design.

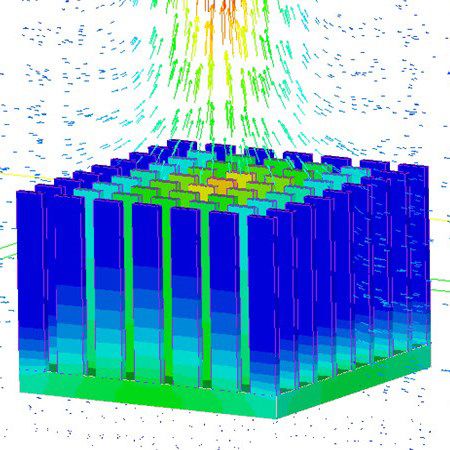

3. Simulation Analysis: After the design plan is completed, the required material and part parameters will be inserted into the simulation software for analysis, and the analysis data will be discussed with the customer.

If optimization and adjustment are required, the revised design will be re-analyzed.

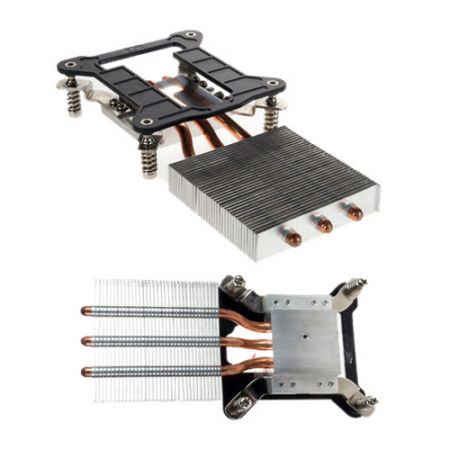

4. Sample Production and Testing: After the customer confirms the design drawing, the prototype sample is manufactured to actually test the performance and appearance of the product. Prototype samples need to be verified and confirmed by customers.

5. Production of Specifications: After discussion, design, analysis, sample preparation, and verification, specifications will be produced and provided to customers for approval.

6. Order and Production: After the customer confirms the quantity, etc., we will prepare materials for production according to the specifications.

- Gallery

Friction Stir Welding Manufacturing Process

What is Friction Stir Welding (FSW)? Friction Stir Welding (FSW) is a solid-state joining technique that produces high-strength, seamless joints without...

Precision Machining Technology

What is CNC precision machining? CNC machining uses CAD/CAM software to create digital programs that drive milling machines for multi-axis cutting. The tool...

Extruded Heat Sink Manufacturing Process

What is the Extruded Heatsink Process? The Extruded Heatsink Process utilizes Aluminum Extrusion Technology to produce heatsinks with integrated fin structures. In...

Skived Fin Heat Sink Manufacturing Process

What is the skived fin heat sink manufacturing process? High-precision metal cutting technology creates a one-piece thermally conductive structure. The...

Stacked Fin Manufacturing Process

What is the stacked fin manufacturing process? Stacked Fin Assembly is a highly efficient heat dissipation structure that combines the advantages of copper...

Bonded Fin Heat Sink Manufacturing Process

What is Bonded Fin Heat Sink manufacturing technology? The Bonded Fin heatsink manufacturing process utilizes a highly efficient heat dissipation structure...